Revolutionizing Infrared Imaging: Umicore's GASIR® Chalcogenide Infrared Materials and iDLC® Coatings Redefine Durability and Performance in Thermal Imaging

Infrared imaging devices are used in a wide range of applications in the defence, space, security & surveillance, communication and healthcare sectors. In recent years, developments in sensor fabrication technology have allowed infrared imaging devices to penetrate the commercial, leisure, industrial and automotive markets as well. When designing thermal optical systems, the optical and opto-mechanical designers look for suitable materials that can be easily manufactured without compromising performance & durability. The interest in new infrared materials has grown rapidly during the last two decades mainly due to the increasing cost of traditional materials such as Germanium and the decrease of the cost of infrared detectors. In response to this Umicore has developed the GASIR® range of chalcogenide optical materials. A key advantage of Umicore’s GASIR® material is that it can be moulded with consistent quality, offering cost effective solutions for high volume government and commercial requirements. The GASIR® material also has the advantage of high transmittance over the IR range, 0.8µm to 16µm with an exceptionally low dn/dt value making it suitable for POA (Passive Optical Athermalization) and PMA (Passive Mechanical Athermalization) optical systems. This offers a big advantage in SWaP-C (Size, Weight, Power and Cost).

The main challenge for IR optics manufacturers over the years remains the task of developing and manufacturing high durability coatings on chalcogenide glasses with the required adhesion due to the thermal expansion coefficient, micro hardness, flexural strength and rupture resistance.

Choosing just the right coating for a particular application can be difficult. Common coating specifications that are normally considered include transmission, reflection and environmental properties. Some coating specifications require performances at angles, absorption, phase, polarization, blocking, etc. Manufacturing high durable coatings without compromises on the key performance parameters is a challenge. Developing, industrializing and volume manufacturing of high durable coatings on Chalcogenide material such as GASIR® is considered as the most challenging task. This document elaborates on the performance of the reference durable coating on the market developed and offered by Umicore iDLC® Coatings.

Chalcogenide glasses, such as GASIR®, due to their unique optical and physical properties, bring new prospects for infrared applications in various fields of industry and science. In this article, you will find the iDLC® coating technology developed by Umicore to overcome the long-term problems associated with the adhesion of coatings to chalcogenide glasses at the same time offer high transmission and excellent durability. This technology was developed and industrialized with more than 1.5 million – iDLC® coated GASIR® lenses shipped so far.

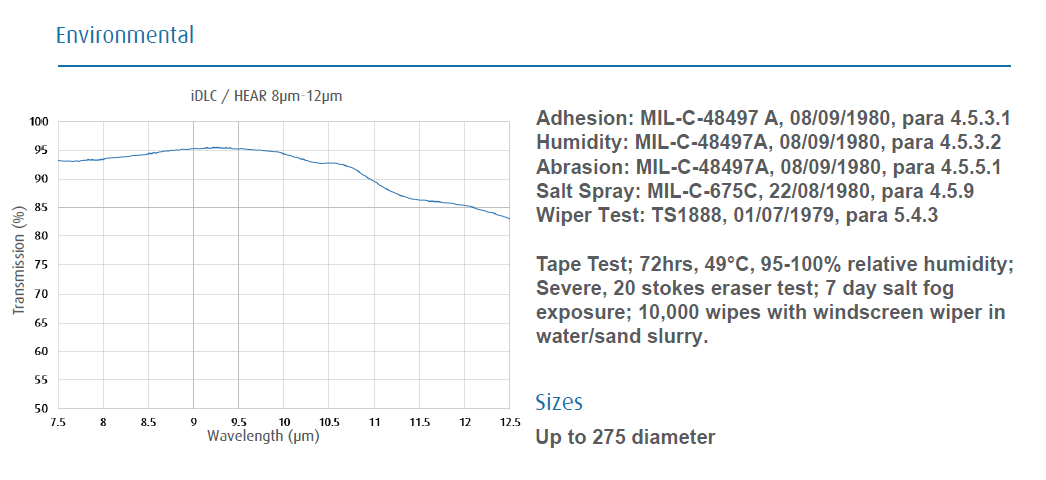

Umicore’s iDLC® Coatings offer exceptional abrasion resistance when deposited onto Umicore’s GASIR1® & GASIR5® substrates. They also offer high transmission in the 8-12µm waveband. It is a rugged coating that can withstand severe abrasion, extended humidity, salt spray and sand wiper tests as per MIL Standards (MIL-C-675C, MIL-C-48497A & TS1888). It complies with the environmental specifications of DLC type coatings on Germanium, while offering comparable transmission and lower reflection values. This coating is applied to the outside surface of a lens or window and is normally used with the high efficiency anti-reflection coating on the second side.

Among many applications, especially for the PVS, iDLC® coatings on GASIR® can replace Ge based lens solution with a stable GASIR® material supply. Also, iDLC® is a perfect substitute for standard Diamond Like Carbon (DLC) coatings with the same result and robust quality.

Typical optical & environmental properties of this coating is:

Refer below a new article by a key customer in the PVS segment highlighting the importance of GASIR® based LWIR solutions.