Germanium for VCSEL Applications

Main characteristics of Germanium for VCSELs

Umicore Germanium has 0 EPD (etch pitch density), which results in a better yield and long term device reliability. The burn-in of final devices may be reduced.

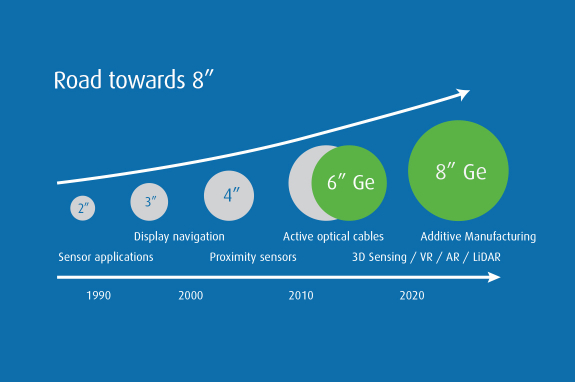

An increase in wafer size has always been the driver of the capacity growth. Larger markets were being addressed with larger diameters. The wafer size went from 2" to 3" to 4" and finally to 6". There is a challenge to migrate GaAs to 8", and 8" Germanium brings a solution here. The true benefit of a larger diameter is a lower processing cost.

Unlike GaAs, with germanium both P-type and N-type can be used, which will make alternative VCSEL designs possible.

Germanium and GaAs wafers have comparable resistivity levels. Even though N-type GaAs mobility is higher, Germanium allows for higher doping levels (Umicore patent pending). In fact, contrary to GaAs, p-type Germanium has similar resistivity to n-type, which creates the freedom for alternative VCSEL designs.

Ge wafers can be made much thinner to improve thermal performance, as Germanium is less brittle. Thickness of 6” Ge wafer for PV, for example, is 225µm. Less back grinding is needed or can be eliminated, improving yield at the end of the line.

Germanium compared to Silicon and GaAs

Property |

Silicon |

GaAs |

Germanium |

|

| Crystal Structure | Diamond | Zincblende | Diamond | Si and Ge are elemental semiconductors with similar large (12") diameter 0 EPD* cyrstal processes |

| Density (g/cm³) | 2.33 | 5.32 | 5.33 | |

| Lattice constant (Å) | 5.430 | 5.653 | 5.658 | Ge and GaAs are lattice matched |

| Bandgap energy at 300K (eV) | 1.12 | 1.42 | 0.66 | |

| Electron mobility (cm²/V-s) | 1350 | 8500 | 3900 | Ge has both high electron and hole mobility |

| Hole mobility (cm²/V-s) | 480 | 400 | 1900 | |

| Melting point (°C) | 1415 | 1238 | 937 | |

| Thermal expansion (1/°C) | 2.6 10-6 | 5.7 10-6 | 5.9 10-6 | Ge and GaAs have similar thermal expansion |

| Thermal conductivity (W/cm°C) | 1.3 | 0.55 | 0.55 | |

| Fracture thoughness (MPa.m1/2) | 0.8 | 0.31 | 0.66 - 0.72 | Ge is twice as tough as GaAs |

* EPD: Etch pitch density, dislocation density